Meet us at VIVE 2026 — Feb 22-25 in Los Angeles. Learn more →

Manufacturing

Predictive maintenance, quality control, efficiency.

Request DemoRequest Demo

[ Predictive Maintenance ]

Prevent downtime before it happens

Ana analyzes your equipment and production data to predict failures and optimize maintenance schedules. Reduce unplanned downtime and extend asset lifespan.

| MACHINE | HEALTH | STATUS |

|---|---|---|

CNC Mill #1 | 94% | Optimal |

Assembly Robot | 67% | Warning |

Conveyor Belt A | 23% | Critical |

Hydraulic Press | 89% | Optimal |

Welding Station | 52% | Warning |

CNC Lathe #2 | 97% | Optimal |

[ How It Works ]

Connect. Predict. Prevent.Connect. Predict. Prevent.

Ana integrates with MES and ERP systems like SAP S/4HANA, Siemens Opcenter, and Oracle Manufacturing Cloud. Connect your production data, and Ana learns equipment patterns to predict failures before they cause downtime.

[ Automated Reports ]

Schedule maintenance and quality reports

Set up playbooks to automatically generate equipment health summaries, quality metrics, and production reports on your schedule.

[ Live Dashboard ]

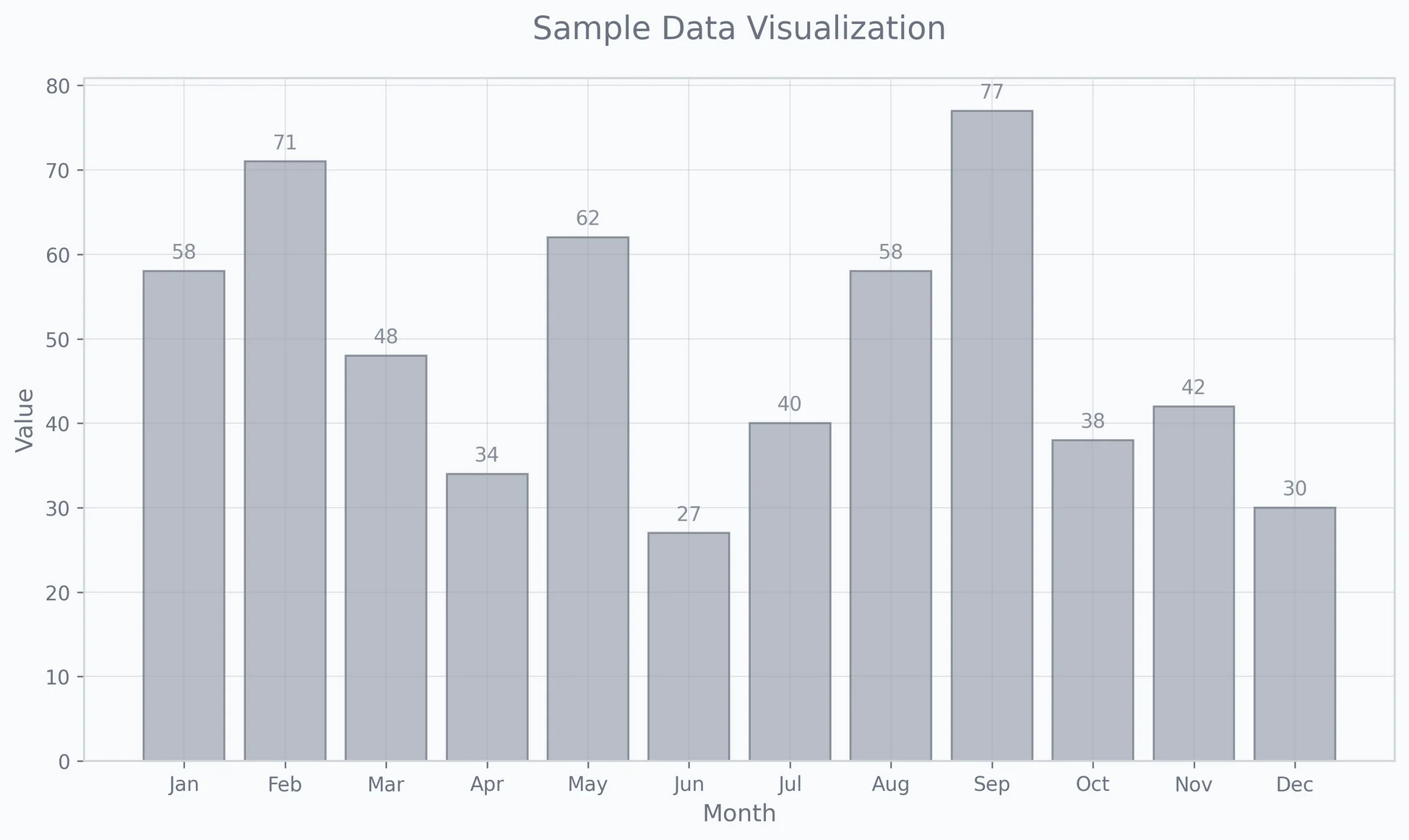

Production metrics at a glance

Track OEE, equipment uptime, defect rates, and production output—all updated in real-time as your lines run.

Turn equipment data into predictive maintenance in minutes, not weeks.